Stainless steel gear pumps are used in the use of electromechanical fever. The cause of electromechanical overheating is a common abnormality of stainless steel gear pumps in the professional process. The overall analysis and testing are as follows: Use the boundary (flow, head) to exceed the gear pump design conditions: select according to the series type spectrum The specific gravity of the medium exceeds that of the gear oil pump assembly machine: the gear oil pump assembly machine is suitable for assembly.

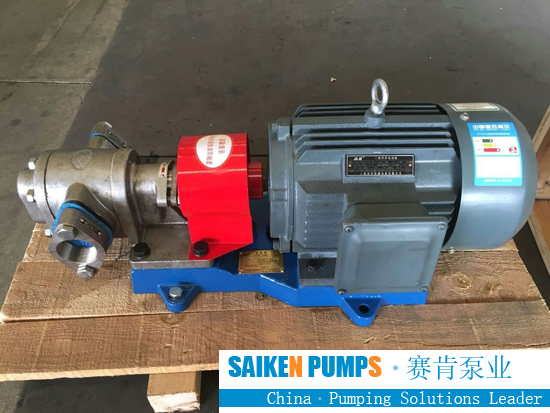

The packing gland pressure is too tight or the mechanical seal spring is adjusted too tightly: adjust the spring shrinkage of the gland or mechanical seal from the beginning. The stainless steel gear pump mainly consists of gears, shafts, pump bodies, safety valves, and shaft end seals. The heat treatment has high hardness and strength, and the shaft is assembled together in a replaceable sleeve to operate. The smoothness of the integral components in the pump is automatically reached for the input medium used by the pump.

The pump has a well-designed oil drain and oil return tank, which is the smallest torque force experienced by the gear in the occupation, so the bearing load is small, the wear is small, and the pump efficiency is high. The pump is equipped with a safety valve for overload maintenance, and a safety valve for full return The pressure is 1.5 times the rated elimination pressure of the pump, and it can also be adjusted according to actual needs within the approved secretion pressure boundary.

The gear pump is mainly composed of gears, shafts, pump bodies, safety valves, and shaft end seals. The gears have high hardness and strength after heat treatment, and the shafts are assembled together in a replaceable sleeve to run. The overall components in the pump are smooth. All of them arrive automatically for the input medium they use when pumping.