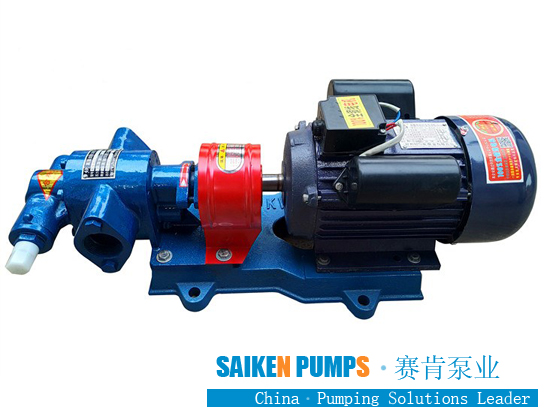

Characteristics of gear pumps

1. Be sure to close the gate valve on the spit line at first.

2. Make the pump complete transformation.

3. In the severe cold season, the liquid storage in the pump body and the water in the cooling chamber of the bearing body should be emptied to prevent freezing and cracking of the parts.

There are many layout types of self-priming pumps. Among them, the operation principle of external-mixing self-priming pumps is to fill the pump casing with water (or water in the pump casing itself) before starting the centrifugal pump. After starting, the impeller twists at a high speed to make the water in the impeller channel flow to the volute. At this time, a vacuum is formed at the inlet, so that the water inlet check door opens, and the air in the suction pipe enters the pump and reaches the outer edge through the impeller channel. On the other hand, the water discharged into the gas-water separation chamber by the impeller flows back to the outer edge of the impeller through the return hole. The water flowing back from the left return hole is ejected into the impeller channel under the effect of pressure difference and gravity, and is crushed by the impeller. After being mixed with the air from the suction pipe, it is thrown to the volute. The submersible pump is resistant to erosion The pump acid-resistant pump, the fire pump moves in a torsional direction. Then it merges with the water flowing from the right return hole and moves along the volute. Because the liquid continuously hits the cascade in the volute and is continuously broken by the impeller, it is mixed with air vigorously to produce gas-water mixture, and it continues to move so that the gas and water cannot be separated. At the exit of the volute, the mixed material is stripped by the tongue and enters the separation chamber along the short tube. The air in the separation room is separated and discharged from the outlet pipe, while the water still flows to the outer edge of the impeller through the return hole, and is mixed with the air in the suction pipe. Repeat the cycle like this, slowly exhaust the air in the suction pipe, make the water enter the pump, and complete the self-priming process. Even if the flow and head of the YCB arc gear pump are controlled within the limits on the label, to ensure that the YCB arc gear pump runs at the efficiency point, the energy-saving effect can be obtained. High-viscosity pumps are divided into belt drive and gear reducer drive. High-viscosity pumps have the following characteristics: low speed, high efficiency, small size, large flow rate, low power consumption, strong self-priming ability, no need to draw oil, and convenient application.

It can be widely used to transport kerosene and kerosene products and factories to transport all kinds of oils and liquids. For example, paint, lubricating oil, glass glue, grease acid, toothpaste and light alkaline (powder processing) liquids, etc.; food processing can be transported Liquids, such as soy milk, yeast, syrup, etc. Loading and unloading of various tank trucks and oil tankers, etc. have a fast speed, high efficiency, and convenient application.

1. The high-viscosity pump will replace the lubricating oil after 100 hours in the working month, and change the oil every 500 hours in the future. The bearing temperature cannot exceed the condition temperature of 35c, and the temperature must not exceed 80c.

Zhangjiakou’s construction of hose pumps surpasses self-stainless steel gear pumps, referred to as stainless steel pumps. When carrying high-viscosity food-like media, stainless steel pumps often exhibit sealing and easy disclosure, gears are not resistant to wear, poor self-priming, and short application life. Only by appropriately choosing the material of the stainless steel gear pump; actively correcting the processing technology of the stainless steel gear pump and better improving the processing accuracy of each component of the stainless steel gear pump and the assembly accuracy of the stainless steel gear pump can better satisfy the majority of customers. Actual demand.

The main events of the stainless steel gear pump when conveying high viscosity food medium are:

, The stainless steel gear pump gear cannot be nitridated, which will mainly cause the food medium to be transported black.

Second, the shaft sleeve of stainless steel gear pump cannot be applied with steel back composite sleeve like the old example. You should just choose a wear-resistant material, such as silicon carbide or zirconia ceramics.

Third, the sealing material of stainless steel gear pump cannot choose graphite packing medium. It should only choose food grade skeleton oil seal or double end face balanced alloy machine seal to ensure the safety of food.

Fourth, the stainless steel gear pump should only be equipped with gear reduction motors, variable frequency motors, and stepless speed regulation motors when transporting high-viscosity food media. Just drop the application speed of the stainless steel gear pump. When the YCB arc gear pump is used in poor winter, after parking, you need to unscrew the lower drain plug of the pump body to drain the medium. Beware of freezing and cracking. 2. The high-viscosity pump should be overhauled after 1500 hours of operation, and introspect The degree of aging of the rubber seal, check whether the exhaust valve is cracked, and wash all the parts in the Roots pump cavity.

3.Add bearing lubricating oil to the bearing body, check that the oil level should be at the middle line of the oil mark, and the lubricating oil should be replaced or made up in time.

4. Inspect whether there is any looseness in the high viscosity pump pipeline and joints. Transfer the high viscosity pump by hand, and try to see if the high viscosity pump is mobile.

5. The test operation should be carried out after the new device. Normally, it must be run for 2 hours without oil and change the oil twice. Because a certain amount of volatile matter will be left in the high viscosity pump during washing, it will be put into normal operation after the normal operation.