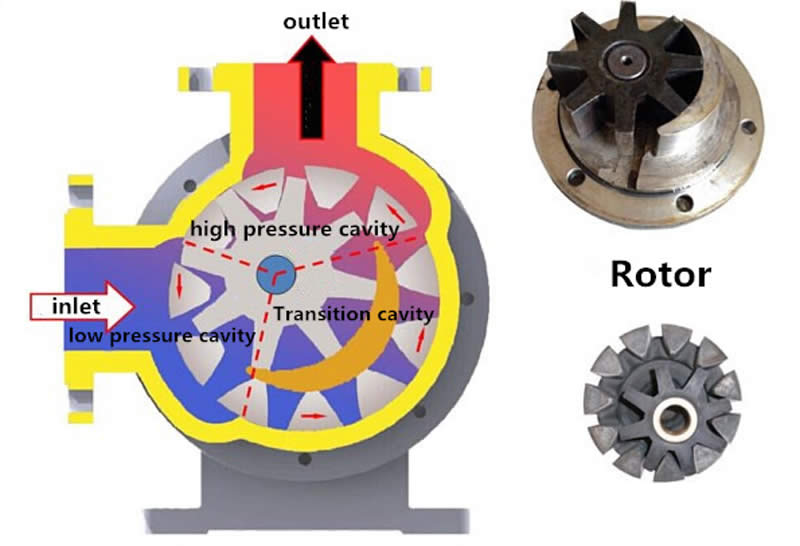

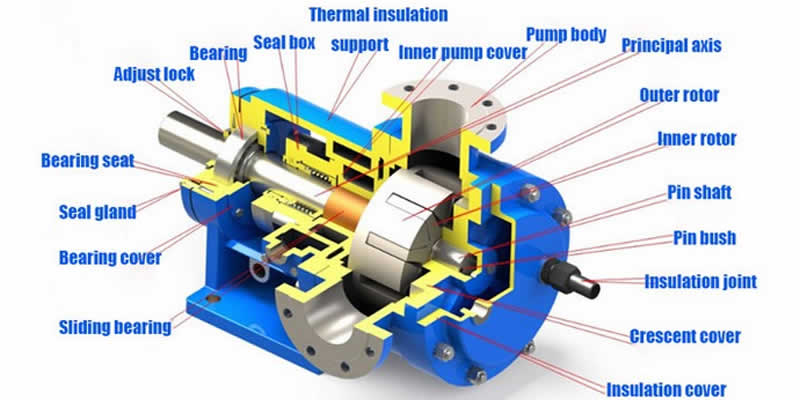

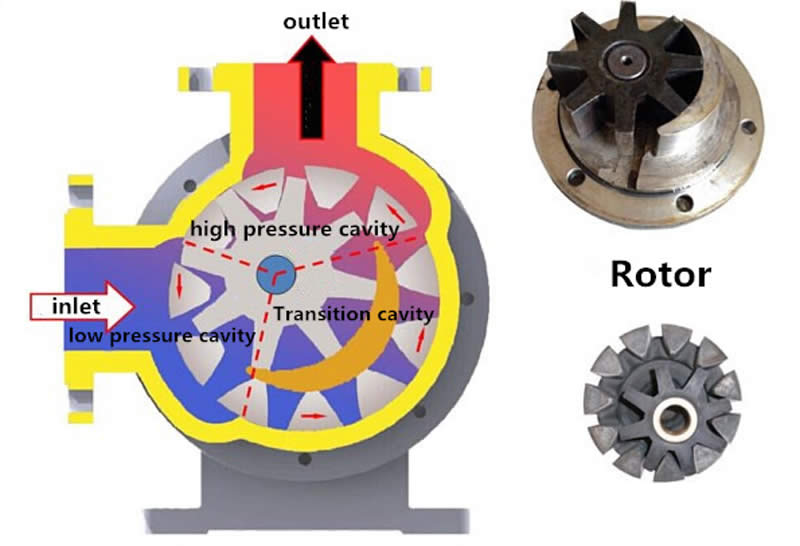

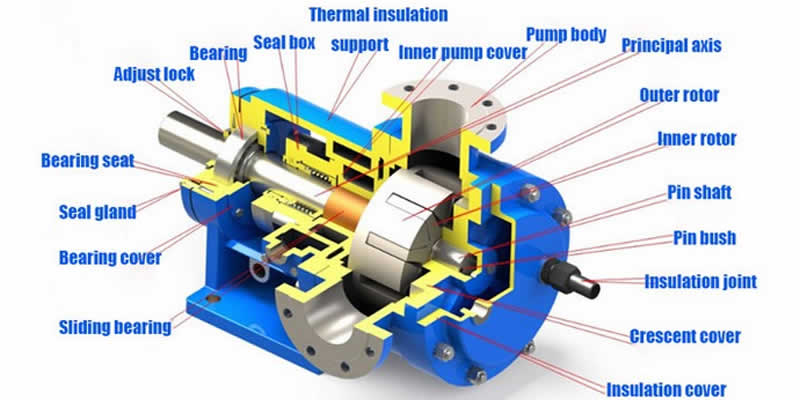

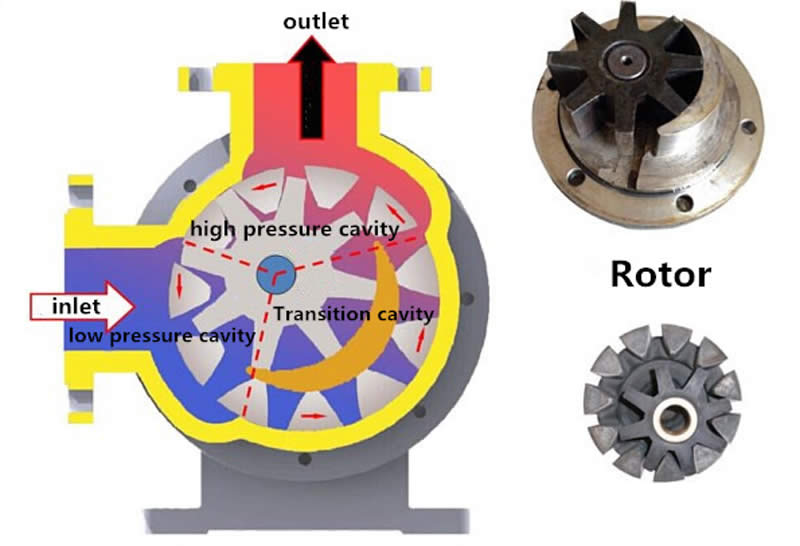

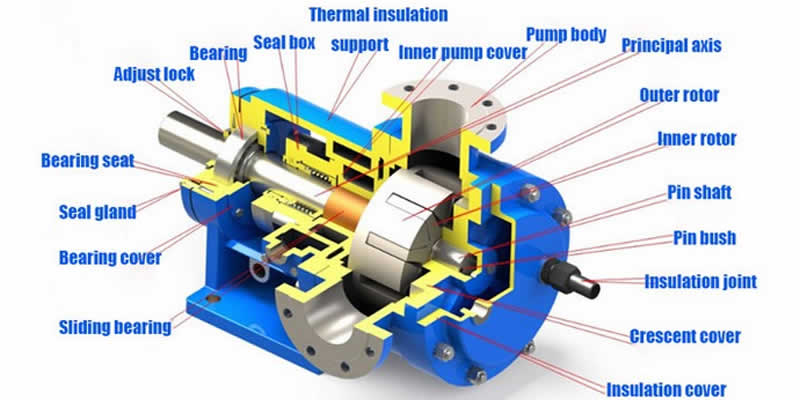

The high-viscosity gear pump of Saiken Pumps pays attention to the daily maintenance work in normal use, and carries out good control according to the corresponding problems and principles. It can fully display the corresponding control and production, and maintain the correct maintenance of the high-viscosity gear pump for a long time. Extended service life. The high-viscosity gear pump adopts the principle of internal meshing. The inner and outer gears are rounded to one side, the other side is separated by the "moon plate", the gears rotate in the same direction, there is no liquid trapping phenomenon, the structure is advanced, the volume is small, the flow is large, the noise is low, and the life is long. long. The unloading element will combine a high flow pump with a low power single pump. The liquid is limited by the structure of the two gear oil pumps due to the fixed displacement. It is generally considered that the high viscosity gear pump can only be used as a constant flow hydraulic source. Various reasons for the poor rotation of the NYP type high-viscosity gear pump can cause the high-viscosity gear pump to heat up and should be handled separately:

1. The assembly is incorrect. The machining reference surface of the two pin holes of the gear oil pump is not the assembly reference surface. If the pin is driven in first, then the screw is tightened and the pump will not move. The correct way is to tighten the screw while turning the high-viscosity gear pump, then drill the pin hole and drive the pin.

2. The working oil outlet is blocked. Clean up foreign objects.

3. There is dirt in the gear oil pump. Disintegrate to clean up foreign objects.

4. The parts inside the pump are not demagnetized. All parts must be demagnetized before assembly.

5. The axial clearance or radial clearance is too small. Re-adjust and adjust.

6. The coaxiality of the pump and the engine coupling is poor. The coaxiality should be within 0.1mm.

High-viscosity gear pumps should be kept in daily use. The electric pump should be placed in a dry, clean and non-corrosive atmosphere. Save each part and replace the same parts. When disassembling the high-viscosity gear pump, each part should be preserved. Pay special attention to the explosion-proof surface of the explosion-proof part, which can not damage the wool, including the insulating gasket and casing. For damage, it is necessary to replace the same new parts. Do not use substitute materials that are lower than the performance of raw materials or parts that do not conform to the original specifications. All parts should be installed in the original position during assembly, and should not be missed.

The surface roughness of the flange of the Sekin pump high viscosity gear pump. The surface roughness of the flange has a great influence on the sealing effect, especially when the non-soft gasket is used, the degree of roughness of the sealing surface is one of the main causes of leakage. For example, the blade of the turning flange surface is a spiral. When the metal gasket is used, if the roughness value is large, the gasket can not block the spiral groove formed by the blade. Under the action of pressure, the medium will be under pressure. Leak along this groove. The soft gasket requires a much lower level of smoothness on the flange surface because it is easily deformed and can block the machining of the knives, thus preventing leakage. For soft gaskets, the flange surface is too smooth and unfavorable because the interface leakage resistance becomes smaller at this time. Therefore, the surface roughness of the flange of the high viscosity gear pump required is different for different gaskets.

Although the high-viscosity gear pump sticking process is relatively simple, the actual construction requirements are quite strict. Only by selecting a good adhesive, it is not possible to obtain a high adhesive strength. It is necessary to select a suitable adhesive, and to apply a suitable adhesive in strict accordance with the correct process, and to strictly follow the correct process to obtain a satisfactory adhesive coating effect. In recent years, surface adhesive coating technology has been widely used in equipment maintenance in China, and it is suitable for the repair of parts and equipment of various materials. The working principle is to directly apply the adhesive of special filler such as molybdenum disulfide, metal powder, ceramic powder and fiber to the surface of the material or part to make it wear-resistant and corrosion-resistant, mainly used for surface strengthening and repair. . Its process is simple, convenient, flexible and reliable. It does not require special equipment. It only needs to apply the glue to the surface of the cleaned parts. After curing, it can be trimmed. It is often operated at room temperature and will not produce parts. Thermal work equivalents and deformations.

In addition, the high-viscosity gear pump flanges are different in form and require different gaskets. Smooth surface flanges are generally only used for low pressure, with soft thin gaskets; under high pressure, if the strength of the flange is sufficient, smooth flanges can also be used, but thick soft mats should be used, or in-band reinforcement A wound gasket of a ring or a reinforcing ring. In this case, the metal gasket is also not suitable because the pressing force required at this time is too large, resulting in a large deformation of the bolt, making the flange difficult to seal. If a metal gasket is to be used, the smooth surface should be reduced to reduce the contact area with the gasket. Thus, in the case where the bolt tension is the same, the pressing stress of the narrowed smooth surface is increased.