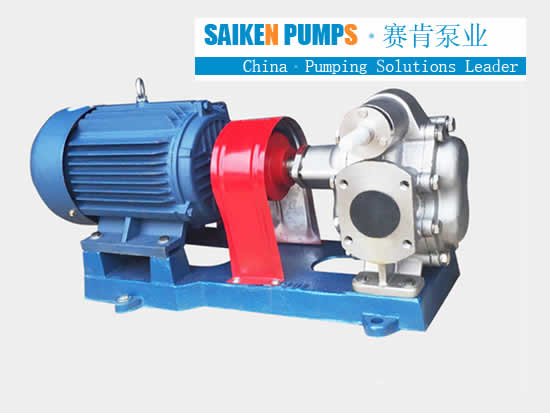

Saiken Pump Industry will explain to you the matters needing attention in the use of the structure and performance of stainless steel gear pumps:

The SUS gear pump produces important performance in specific use. It adopts a certain structure and performance in the design, and works and uses according to certain usage methods and principles. It can exert good advantages and performance in the transportation of liquids. The following introduces the structure and performance of the stainless steel gear pump, and the matters needing attention in use:

1. The function of the stainless steel gear pump: suck gasoline from the fuel tank and supply enough gasoline with the specified pressure to the fuel system. The pressure of the electronic control gasoline injection system is generally: multi-point injection: 0.25~0.35Mpa; single-point injection: 0.1Mpa. The turbine type stainless steel gear pump is mainly composed of turbine, casing and pump cover. The turbine is driven by an electric motor. Under the action of centrifugal force, the turbine closely adheres to the housing and drives the gasoline from the oil inlet side to the oil outlet side through a narrow gap to pressurize. The fuel passes through the inside of the motor to cool the motor.

2. Installation position: There are two main installation positions for stainless steel gear pumps, namely, installed in the fuel supply pipeline and installed in the gasoline tank. But the latter is widely used, and the electric gasoline pump is usually suspended vertically in the fuel tank by a fuel pump bracket fixed on the fuel tank. Two-stage stainless steel gear pumps need to pay attention to some matters and methods in use. Because gasoline is very volatile, and the temperature rises when the pump is working and a partial vacuum is generated when the oil is sucked, the gasoline vaporizes and the pump oil volume decreases, resulting in output oil pressure. fluctuation. Two-stage electric gasoline pumps are widely used in modern automobiles, that is, two electric gasoline pumps are connected in series to increase the fuel supply capacity. When the oil pipeline is blocked or the gasoline filter is blocked, the gasoline pressure exceeds the specified value, the pressure limiting valve opens, and the gasoline flows back to the oil inlet side. After the engine is turned off, the one-way valve is closed to avoid reverse flow of gasoline in the oil pipeline and maintain a certain residual pressure in the oil circuit to facilitate the restart of the engine.

3. Composition: The stainless steel gear pump is mainly composed of a pump body, a permanent magnet DC motor and a shell. In addition, a safety valve and a one-way valve are installed.

Safety valve is also called pressure limiting valve (or overflow valve), which is mainly composed of valve seat, sealing steel ball and spring. The check valve is installed at the oil outlet of the stainless steel gear pump. The pump body is the main body of the electric gasoline pump. According to its structure, it can be divided into: roller type, turbine type, gear type, etc.

Roller type stainless steel gear pump is composed of shell, cylindrical roller and rotor. The five rollers can slide radially in the slot of the rotor, and there is a certain eccentricity between the rotor and the housing. The rotor is driven by a DC motor to rotate. Under the action of centrifugal force, the rollers are pressed tightly on the inner surface of the pump body to form five relatively independent sealed cavities. When rotating, the volume of each sealed cavity changes continuously. At the oil inlet, the volume increases to form a certain vacuum, and the filtered gasoline is sucked into the pump. At the oil outlet, the volume becomes smaller, the pressure rises, and the gasoline passes through the DC motor to push open the one-way valve and output.