China Food Grade Lobe Pumps for Chocolate,Food Grade Lobe Pumps manufacturer! Suitable for high viscosity liquids,quality assurance and best price!...

read more

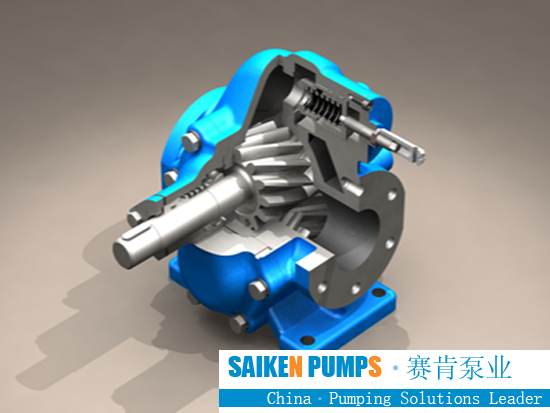

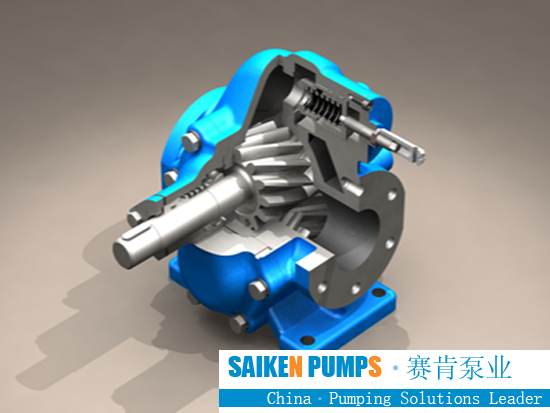

There are many differences between lobe pumps and gear pumps: 1. Volume: Due to its compact design, the lobe lobe pump requires a small footprint. No additional space is required to service the pump. Standard flange, diameter can be adjuste...

2020-07-15