The complete high viscosity gear pump consists of a high-viscosity pump and a geared motor mounted on a common base. The geared motor is connected to the SS high viscosity gear pump with an elastic coupling, the coaxiality is less than 0.1 mm, and the inclination angle should not be greater than 1 degree. Do not hit with a hammer when installing the coupling, so as not to damage the seals, gears and other parts of the high-viscosity gear pump. If the high-viscosity gear pump is driven by a belt pulley, a bracket should be provided to prevent the driving gear bearing from receiving radial force. When tightening the anchor screws of high-viscosity gear pumps and motors, the force of the screws should be even and the connection should be reliable. When rotating the coupling by hand, you should feel that the high-viscosity gear pump can rotate easily without any abnormalities such as jamming, and then you can piping.

The inner diameter of the suction pipe of the high viscosity pump should be large enough to avoid narrow passages or sharp bends, reduce elbows, remove unnecessary valves and accessories, reduce the installation height of the high-viscosity pump as much as possible, and shorten the length of the suction pipe. Reduce pressure loss. The sealing of pipe joints and other components should be good to prevent air intrusion, so as to control the occurrence of cavitation and cavitation.

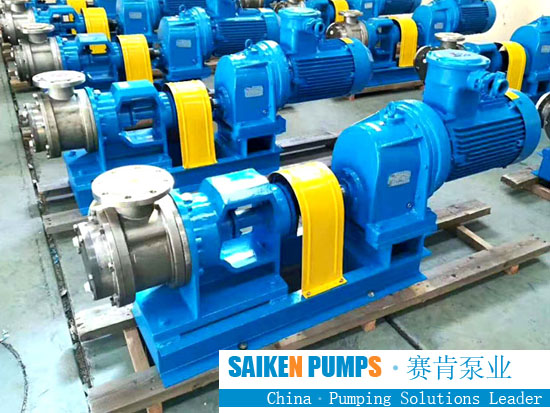

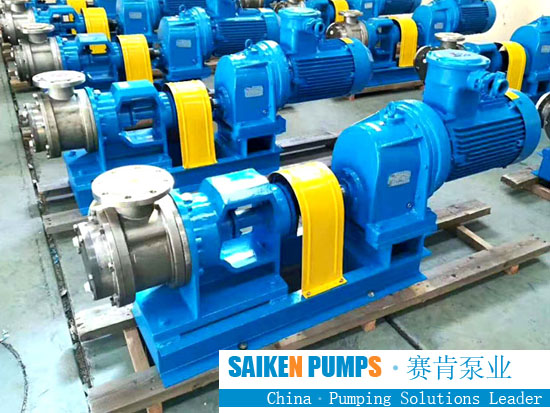

saiken pump industry strives for perfection and implements every component, and strives to be exquisite