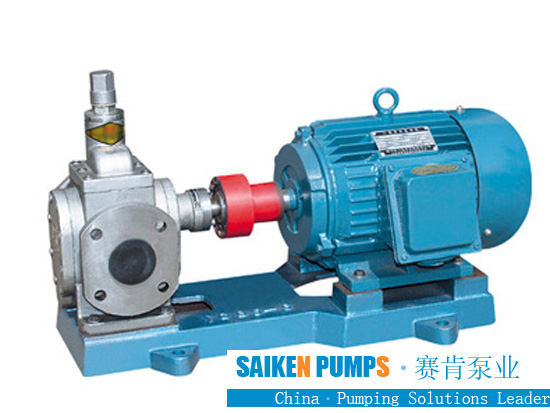

The gear pump is an external meshing positive displacement pump with a simple structure, less after-sales, and easy maintenance. However, in reality, some users are worried that they cannot install the stainless steel gear pump after they are disassembled when they encounter some failures when using the gear pump. For this problem, today I will talk about how to install the gear pump after disassembly.

1. First, check the disassembled parts. If you find any parts with serious wear and tear, repair or replace them, such as seals and bearings, they must be replaced.

2. First assemble the protective cap, gasket, nut, adjusting screw, safety valve core, valve body, etc. on the safety valve of the gear pump and put it aside for later use. For pumps without safety valves, this step is omitted.

3. Install the gears on the main shaft and the driven shaft respectively, pay attention to the rotation direction of the gears when assembling, and fix the non-return nut.

4. Put the composite sleeve on the bearing sleeve and install them on both ends of the gear of the gear pump. Install the gear shafts in the pump body together and check whether the rotation is normal.

5. Put the prepared gasket between the pump cover and the pump body, and install the pump cover on the pump.

6. Install the packing seal or mechanical seal on the main shaft, and install the sealing gland.

7. Install the coupling and elastic block on the pump shaft and motor shaft respectively, and install the whole machine.

Gear pump manufacturers and suppliers from China