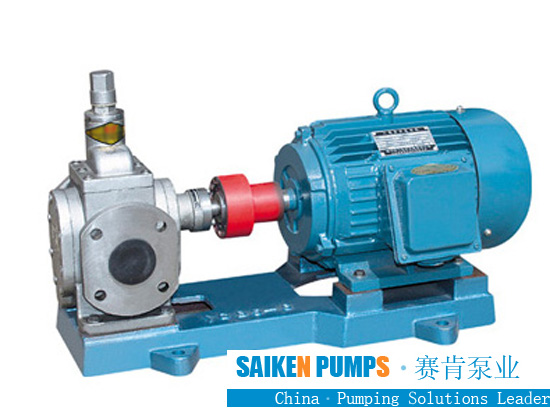

Gear pumps are suitable for heavy oil, fuel oil, mechanical oil, and other oily media with lubricity and similar performance with a medium temperature of ≤170℃ and a viscosity of no more than 100mm²/s. This type of pump is generally used in petroleum, chemical, Mechanical engineering and other occasions.

There are two types of gear pumps: external gearing and internal gearing. The former is simple in structure, cheap in price, and widely used; the latter is complicated to manufacture and uses less, but due to its small size, light weight, uniform flow, high efficiency, and long life, it is suitable for some compact size and weight requirements. On light machines (such as airplanes). In order to improve the flow uniformity and operation stability of the pump, helical gears or herringbone gears can be used, and the structure can be made into a single-stage pump, a two-stage pump or a double pump.

Compared with vane pumps and plunger pumps, gear pumps have lower efficiency, and the oil suction height is generally not more than 500mm. Because of low efficiency, low pressure and low flow, it is mostly used in simple hydraulic systems with medium speed and low force, and sometimes used as an auxiliary hydraulic pump. General engineering machinery, mining machinery, agricultural machinery, machine tools and other industries can be applied.