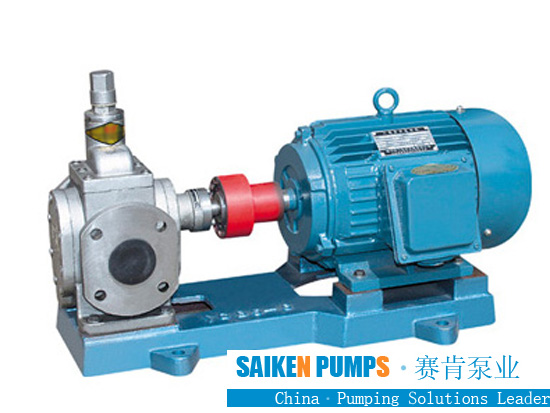

Gear pump is a common type of positive displacement pump. They are considered to be fixed displacement pumps, which means that a constant amount of liquid movement is provided by providing a constant rate of rotation of the pump.

They generally work in the following areas:

The flow range is between 1 and 1500 gpm

The total head (pressure) range is between 10 and 2500 pounds

horsepower range of 0.5 and 2,000 horsepower

Transparent liquid viscosity range 2000000 SSU

How do they work?

Their work uses standard types of gears, spur gears or bevels, and the rotation of herringbone gear sets for special applications. The pump that moves the gear to generate suction, and the fluid sucked to the gear is in the inlet. Then move the liquid between the gear teeth of the rotating gear and the wall of the housing and guide the fluid flow to the discharge port, where the pressure near the outlet of the pump as the volume of the housing becomes smaller continues to build.

There are two main types of , these two consist of a drive gear (gear pressed) and an idler gear (gear pressed). External gear pumps, usually in low-flow applications, use two side-end spur gears, helical gears, or herringbone gears to mesh together, while internal gear pumps consist of a small idler gear, suitable for larger transmission gears. The internal configuration includes a crescent-shaped internal barrier that can flow directly through the pump. These two types often contain a built-in pressure relief valve to protect the pump and the system, and the valve discharge pipeline is inadvertently closed.