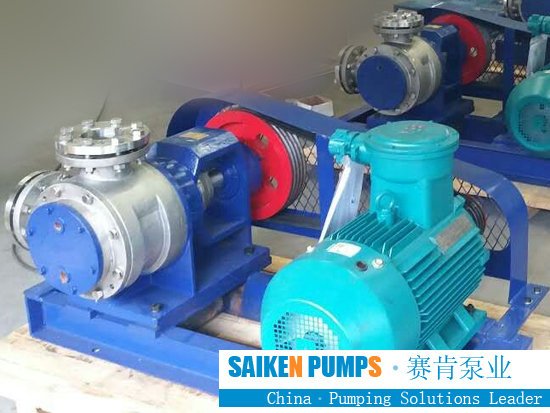

The high-viscosity gear pump has the characteristics of simple structure, easy maintenance and maintenance, safe and reliable use, and is composed of main parts such as the pump body, pump cover, gear, shaft end seal, etc. The high viscosity pump adopts a bridge-type external belt pulley transmission method, which has a simple structure and low speed , Low noise and other characteristics are widely used in machinery, petrochemical, metallurgy, textile, medicine, food, paper, light industry and other industries.

Proper installation and use of the belt can not only extend its service life, but also protect the pulley and machinery, such as keeping the belt clean and preventing the belt from being too tight.

1. Before installing the SS high-viscosity gear pump, remove and clean the greasy, lubricating oil, cotton wool, etc. attached to the belt pulley. If there are foreign objects or dirt on the belt, it will cause abnormal rotation of the wheel and abnormal walking of the belt.

2. When installing the belt, try to avoid reluctantly turning up the belt or bending the belt, which will cause the early damage of the belt.

3. Confirm the surface and back of the belt according to the seal on the belt, and also confirm whether the belt jumps over the side of the guardrail or has the necessary contact with the machine.

4. When installing, you must first relax the tension adjustment mechanism such as the tension wheel before proceeding.