Saiken Pump Industry will explain to you the application range of large-flow gear pumps, the principle and characteristics of surface adhesion of large-flow gear pumps. In recent years, surface adhesion technology has been widely used in equipment maintenance in China, and is suitable for various materials. The repair of parts and equipment. The working principle is to directly apply the adhesive with special fillers such as molybdenum disulfide, metal powder, ceramic powder and fiber to the surface of the material or part to make it wear-resistant and corrosion-resistant. It is mainly used for surface strengthening and repair. Its process is simple, convenient and flexible, safe and reliable. It does not require special equipment. It only needs to apply the prepared glue to the surface of the cleaned part, and it can be repaired after curing. Operating at room temperature will not cause thermal equivalent effects and deformation of the parts.

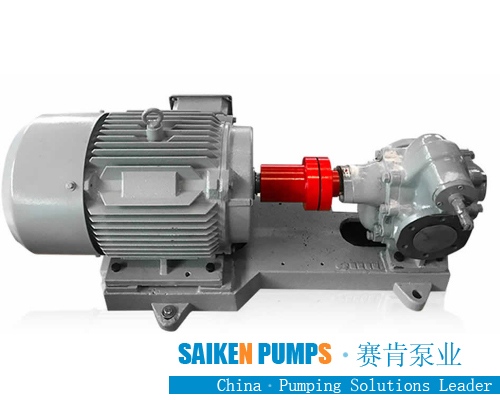

The high-flow gear pump transmission is a mechanical transmission that uses the gear teeth of two gears to mesh with each other to transmit power and movement. According to the relative position of the gear axis, it is divided into parallel shaft cylindrical gear transmission, intersecting shaft conical gear transmission and cross shaft helical gear transmission. It has the characteristics of compact structure, high efficiency and long life.

The high-flow gear pump is equipped with a safety valve as overload protection. The total return pressure of the safety valve is 1.5 times the rated discharge pressure of the pump. It can also be adjusted according to actual needs within the allowable discharge pressure range. But note that this safety valve cannot be used for long-term operation of a pressure reducing valve, and can be installed on the pipeline when necessary. Seen from the extended end of the main shaft toward the pump, it rotates clockwise. The application range of large-flow gear pumps can be used as transmission and booster pumps in oil delivery systems; as fuel pumps for conveying, pressurizing and injection in fuel systems; and as lubricating oil pumps in all industrial fields use.

Gear pump manufacturers and suppliers