High-viscosity gear pumps have different materials and structures. According to different structures, they have good use value and role in application, and are used in different fields. The support or flange of the high-viscosity gear pump and its drive motor should use a common installation foundation, and be reasonably installed and used according to a certain method. The foundation, flange or support must have sufficient rigidity to reduce the gear oil pump Vibration and noise generated during operation. The interior of the high-viscosity gear pump needs to be installed and worked according to the corresponding process. The motor and the gear oil pump must be connected by an elastic coupling, the coaxiality is less than 0.1 mm, and the inclination angle should not be greater than 1 degree. Do not hit with a hammer when installing the coupling, so as not to damage the gears and other parts of the SS high viscosity gear pump. If driven by pulleys, sprockets, etc., brackets should be provided to prevent the driving gear bearings from being subjected to radial forces. When tightening the anchor screws of high-viscosity gear pumps and motors, the force of the screws should be even and the connection is reliable. When rotating the coupling by hand, you should feel that the heat preservation gear pump can easily rotate, and there is no abnormal phenomenon such as jamming before you can pipe. The oil suction pipe inside the high viscosity gear pump should be properly installed and used. The inner diameter of the oil suction pipe should be large enough to avoid narrow channels or sharp bends, reduce elbows, remove unnecessary valves and accessories, and reduce the installation of the pump as much as possible. Height, shorten the length of the oil suction pipeline to reduce pressure loss. The sealing of pipe joints and other components should be good to prevent air intrusion and thus control the occurrence of cavitation and cavitation. Before starting operation, fill the housing of the gear pump with the liquid to be transported to facilitate starting. If the ambient temperature is lower than the freezing point, hot steam should be pre-introduced into the pump for pre-heat treatment before the gear oil pump can be started. The rotation direction of the high-viscosity gear pump should be consistent with the inlet and outlet.

If the high-viscosity gear pump is run once, or used after a long period of inactivity, it will run for about an hour under no-load or light-load conditions. If abnormal temperature rise, leakage, vibration and noise are detected in advance during the running-in phase, the machine should be shut down for inspection. When the gear pump is stopped with load, it can also prevent the pump from reversing and generate a partial vacuum in its output pipeline. It should be noted that the outlet check valve cannot be reversed or stuck. Valves and other protective devices should also be installed on the outlet pipeline of the high-viscosity gear pump, so that once the outlet channel of the pump is blocked, the valve can be opened to relieve the pressure. The valve can be cast integrally with the pump body or pump cover or can be assembled separately. For high-viscosity gear pumps that require forward and reverse rotation, valves are required on the inlet and outlet pipes. The production and use of SS high viscosity pumps are carried out in accordance with certain procedures and methods to ensure the reasonable use and work of internal gear oil pumps and insulated gear pumps. Do not cause some abnormal conditions that affect the normal use of the pump because of unreasonable use. It will outweigh the gains.

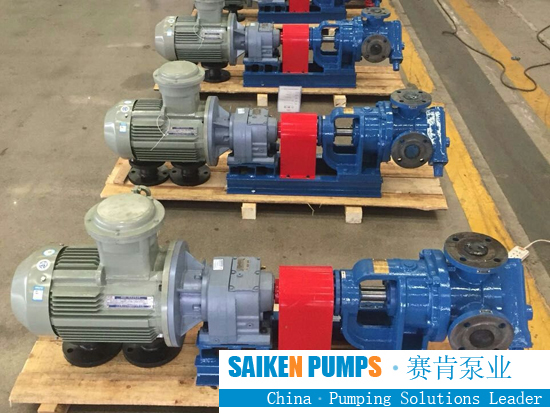

High viscosity gear pump is mainly used for conveying high viscosity, high consistency resins, polyethers, 107 gums, glass gums, polyether polyols, various epoxy resins, unsaturated resins that cannot be conveyed by ordinary gear pumps. , Bitumen, and various high-viscosity media like pastes with poor fluidity, high viscosity, and high consistency. Reliable quality, smooth operation, low noise and long service life.

13 main features of high viscosity gear pump

1. The flow is stable: there is no pulsation and pressure peaks, and there will be no pipe vibration.

2. Versatility: Only by adjusting the position of the rotor shaft, the same pump can come out to dilute the solution and also come out high viscosity liquids such as asphalt, syrup, resin, polymer, etc.

3. Reversibility: You can reverse the flow of liquid by changing the direction of rotation of the gear, both directions can give full play to the performance of the pump

4. Self-priming: The high vacuum is generated by the pump, allowing rapid self-priming at a large self-priming height, depending on the physical characteristics of the pumped liquid (temperature, vapor pressure, viscosity, etc.).

5. Recommendation: There are only two moving parts: driving wheel and moving wheel, and only one shaft seal.

6. Sturdy heavy-load structure: low speed. The outer housing of the extra large ball bearing can bear axial and radial loads.

7. Low wear rate: Because the driving wheel and driven gear are not in multiple relationship. This means that wear can be evenly distributed on each gear. Because each gear on one gear touches each gear on the other gear the same number of times.

8. Wear adjustment system: The wear of the rotor edge can be compensated by adjusting the position of the rotor shaft. In this way, even in the case of considerable wear, the stability of the pump can be guaranteed.

9. Simple maintenance and low maintenance rate: it can be inspected and adjusted without moving the pump, pipeline or pump driving device.

10. Interactivity: The design of standard components can realize the replacement between different materials and characteristic parts. For example: there are a variety of shaft seal systems to choose from, and it is also possible to install jacketed housings and shaft covers instead of standard components.

11. The position of the port can be changed: the pump casing can be rotated on the bearing box to suck and discharge liquid from different positions.

12. Preheating: The heating jacket is either cast integrally with the outer shell, or installed on the end cover, or installed on the packing gland.

13. Bypass valve: The bypass valve is installed on the pump and is easy to adjust. In some models of the pump, a double valve is used with a heating jacket.